Before injection of PPG at field condition, following procedure shall be done in lab condition and then based on the lab results, PPG injects in the well.

Synthesis of PPG based on reservoir condition(Each reservoir specific formula)

Specific formula shall pass synersys test.(Means shall resist at reservoir condition)

Swelling ratio, Adsorption, Resistance Factor and Residual Resistance Factor of costumed PPG shall measured.

Based on reservoir simulation models, well log data, well test data, production history and …the required amount of PPG will be estimated.

Conceptual and field injection procedures will be designed.

PPG’s injection will start and based on well head pressure data the PPG’s size will be adjusted to reach desired injection pressure.

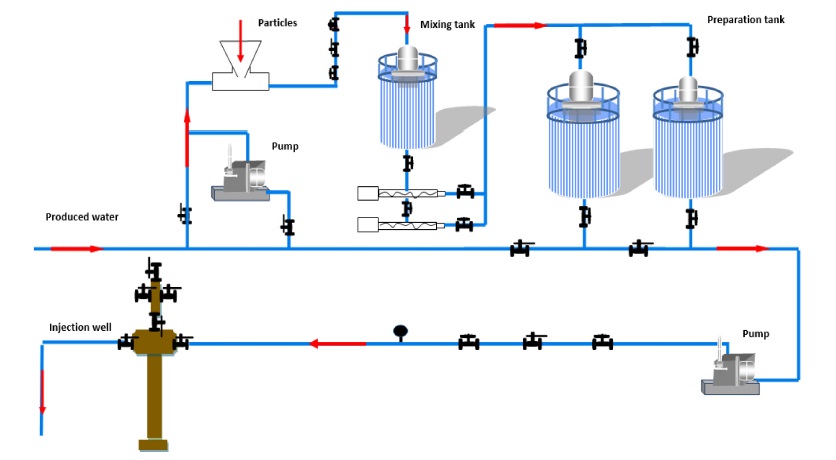

The injection system for particle gel treatment is simple compared to traditional polymer gel system. The traditional gel system needs to prepare polymer and crosslinker before injection and the combination of these two components is sensitive to formation water. Fresh water is required for the preparation of this gel system. Particle gel can overcome the inherent disadvantage in the traditional system because it only has one component during the injection. The particle suspension, therefore, can be prepared with produced water not the fresh water, which can protect the environment, save the valuable fresh water and make the injection process easier. The produced water carried particles into mixing tank. After well-mixed in mixing tank, the particle suspension is delivered into preparation tank to make the concentration of the suspension the same as the designed concentration. Then the suspension will be injected into injection wells by the pump.

During the particle injection process, more attention should be attached on real-time injection pressure monitor to adjust the initial design parameters such as particle size and particle suspension concentration. The criteria for pressure monitoring is to keep the injection pressure gradually increasing because this rising trend is an important indicator to reflect if particles have been propagated deeply into the reservoir. Either nearly no increase or sharply increase of the injection pressure is harmful for the effect of treatment. The high increased pressure may damage formation by creating fractures and no pressure increase always indicates that the treatment will be probably ineffective in the end. If these conditions occur, we need to do necessary adjustment of particle size or suspension concentration.