Excess water production is a very serious problem during water flooding of reservoir formations. This problem may be due to the following reasons: weak macroscopic sweep efficiency, lack of conformance control.

Some of the problems that cause excess water production are High water cut, Separation, Corrosion, Chemical cost, etc. In general, the following two methods are used to resolve this problem: mechanical blocking devices & chemicals method.

Types of Gels

There are 3 main types of gels:

In situ gel:

A gelant is injected into a formation; where a gel forms under reservoir conditions.

Preformed gel:

A gel is formed in surface facilities; then injected into the reservoirs.

Preformed particles gel (PPG):

A gel is formed in surface facilities; Dried in high temperature, break in pieces, sieved and mixed with water. Then injected into reservoir.

Preformed particle gel (PPG) is a particled superabsorbent crossklinking polymer that can swell up to 200 times its orginal size in brine. The use of PPG as a fluid-diverting agent to control conformance is a novel process designed to overcome some distinct drawbacks inherent in in-situ gelation systems.

Recently, using preformed Particle gel to control conformance in mature oil fields is recommended , because it can overcome some distinct drawbacks inherent in in-situ gelation systems, such as difficulty of gelation time control, potential damage of low-permeability hydrocarbon zones, and the uncertain nature of gelling caused by the shear in surface facilities and porous media.

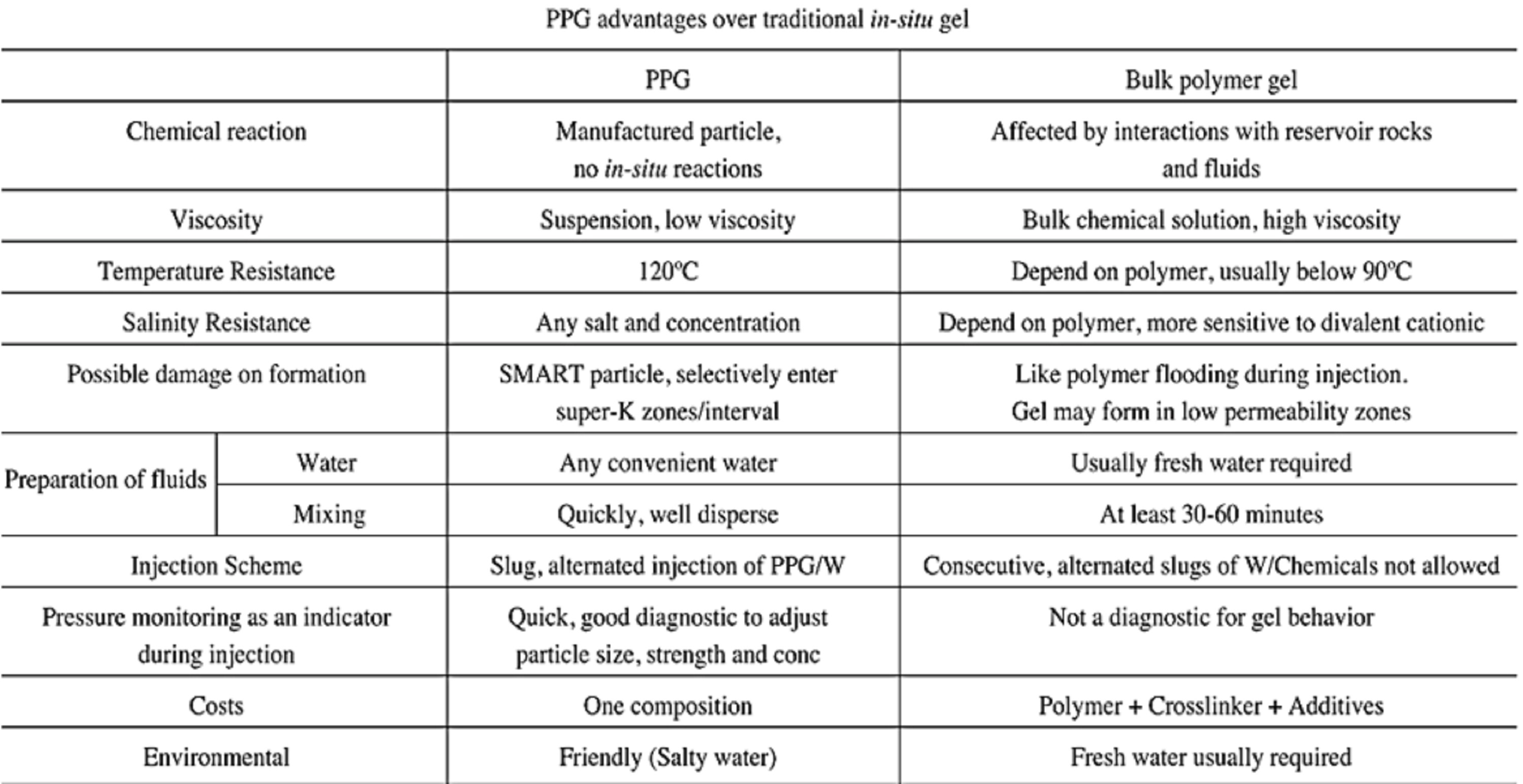

PPG Advantages

Also Wide ranges of operational conditions of PPG are:

- Sandstone and fractured carbonate reservoirs:

- Temperature from 20 to 120 °C

- Salinity from 2,000 to 280,000 mg/l.

- Concentration from 1000 to 5000 ppm

- Permeability from 20 to 56000 md

- Lithology: Carbonate, Sandstone, Limestone

Here is no negative effect with PPG injection in all 4800 wells.

Researches and Publications

We could extended the thermal applicability of PPG from 120oC to 145oC (Saghafi et.al 2016a). In our recent experimental studies, we have focused on investigation of different characteristic of PPG.

These characteristics include Viscosity (Saghafi et.al 2016b), mechanical entrapment (Saghafi et.al 2017a), swelling ratio (Saghafi et.al 2017b) and retention (Saghafi et.al 2018) of PPGs.

Besides publications mentioned above, we are currently working on field project of PPG treatment named “Experimental Study on Water Shut-off By Preformed Particle Gels (PPG) and Designing Conceptual Pilot Plan for Balal Oil Field”.

List of chemicals used to synthesis the PPGs

Based on the reservoir condition of, the PPGs formulated and synthesized by chemicals that listed in below table:

|

Name

|

|

Acrylamide

|

|

N,N-Dimethyl Acrylamide

|

|

Monomer 1

|

|

Monomer 2

|

|

N,N’-Methylenebis (Acrylamide)

|

|

Ammonium Chloride

|

|

N,N’,N,N’ Tetramethylethylenediamine

|

|

Sodium Persulfate

|

|

Nano Clay Montmorillonite Na+

|

|

Nitrogen Gas

|